| Sign In | Join Free | My qualitytoyschina.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My qualitytoyschina.com |

|

Brand Name : HT

Model Number : 10" BLIND FLANGE

Certification : ISO,BV,SGS

Place of Origin : CHINA

MOQ : 1 PIECE

Price : Negotiation

Payment Terms : T/T, Western Union, MoneyGram,30% T/T IN ADVANCE 70% BEFORE SHIPMENT, L/C

Supply Ability : 10000 PIECES PER YEAR

Delivery Time : 15-20 Working Days

Packaging Details : Woodcase, pallet, woven bag etc. or as per your requirement

Size : 10"

Process : Forged

Class Rating : 150#

Sealing Face : RF

Face Finish : Smooth /Stock Finish

Application : Chemical /Oil/Gas/Energy

Standard : ASME B16.5

Material : Nickle Alloy Steel

BLIND FLANGE ASTM B564 UNS: N10675 ASME B16.5 RF GROOVED 150PSI Ø 10"

1. Flange Specification:

| Pipe | Flange Specification | Raised Face | Drilling Specification | Weight | ||||

| Norminal Pipe Size | A | C | G | H | I | J | ||

| Outside Diameter | Overall Diameter | Flange Thickness min | Face Diamter | Number of Holes | Bolt Hole Diameter | Diameter of Circle of Holes | kg/ piece | |

| in mm | in mm | in mm | in mm | in mm | in mm | |||

| 10 | 10.75 273.0 | 16.00 406.4 | 1.190 30.20 | 12.75 323.9 | 12 | 1.000 25.40 | 14.25 362.0 | 28.8 |

2. Hastelloy B3 Datasheet:

UNS: N10675

ASTM: B 333, B 335, B 619, B 622, B 626, B 366, B 472

ASME: SB-333, SB-335, SB-619, SB-622, SB-626, SB-366

| Ni | Cr | Mo | Mn | Cu | Si | C | S | P | Ti | Al | Co | Nb | V | Fe | |

| MIN | 65.0 | 1.0 | 27.0 | – | – | – | – | – | – | – | – | – | – | – | 1.0 |

| MAX | – | 3.0 | 32.0 | 1.0 | 0.2 | 0.1 | 0.01 | 0.01 | 0.03 | 0.2 | 0.5 | 3.0 | 0.2 | 0.2 | 3.0 |

A. Resists hydrochloric acid at all concentrations and temperatures

B. Withstands wet HCl gas, sulfuric, acetic and phosphoric acids

C. Excellent resistance to pitting and to stress corrosion cracking

A. Acetic acid production, initial phase in presence of iodide catalyst

B. Methyl methacrylate production with hot 98 H2SO4

C. Production of herbicides, insecticides, ethylene glycol, ethyl benzene

Density: 0.333 lb/in3 Melting Range: 2500- 2585°F Electrical Resistivity: 651 Ohm-circ mil/ft

| Temperature, °F | 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 | 1600 |

| Coefficient* of Thermal Expansion, in/in°F x 10-6 | 5.7 | 6.1 | 6.3 | 6.5 | 6.6 | 6.5 | 7.1 | 7.6 |

| Modulus of Elasticity Dynamic, psi x 106 | 30.9 | 30.1 | 29.3 | 28.3 | 27.2 | 26.5 | 24.9 | 23.3 |

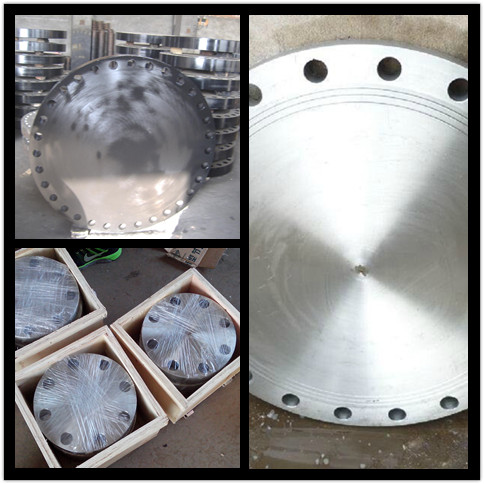

3. Product Showcase:

4. Packaging Details

5. Quality Assurance

|

|

Rf Grooved 150psi Blind Flange / Astm B564 Nickle Alloy Steel Flanges Images |